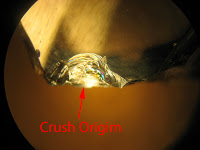

California Failure Analysis Lab routinely performs tempered glass failure analysis. In this case the glass expert determined that the tempered glass failed as a result of a pointed object that created crush damage that penetrated the compressive layer of the tempered glass. The glass was a large piece 10 mm thick. Thus, the compressive layer is approximately 2 mm thick on each face. It is interesting to see how the failure initiates on the surface and progresses inward. Later the residual tensile stress causes the entire glass panel to break into small “cubes”. On the face of the panel there is a glass crush point.