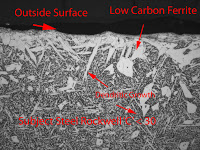

Metallurgists at Read Consulting were asked to perform a metallurgical failure analysis of a cast steel pipe that had burst. The pipe was in a high pressure concrete delivery system that was pumping concrete to a top floor of a parking garage. The pipe burst unexpectedly, and a worker was injured. A part of the analysis was to look at the steel’s micro-structure. The drawing specifies 8630 steel that is heat treated after casting. The heat treat consists of two steps. First it is austenized then brine quenched. It is then tempered.. The final hardness was to be Rockwell ‘C’ of 40 or higher. The hardness of the failed pipe was less than Rockwell ‘C’ of 30. An exemplar was also examined and found to meet specifications. Comparing the micro-structures is telling. The exemplar micro-structure is what would be expected of a tempered cast 8630 steel. The subject steel has an “as cast” micro-structure. It is evident that the failed pipe had a manufacturing defect because it had not been heat treated after casting. The as cast steel has lower strength, and it will wear faster than a steel that has been heat treated. This is part of the reason this pipe failed unexpectedly.