A new barn built with galvanized and painted steel demonstrated the type of defect shown in the photograph on the left. After less than one year verticle lines of white spots appearedon the painted surface. These spots were examined by a coating engineer to determine the root cause of the defect.

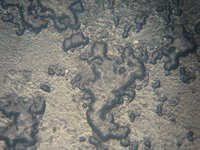

Associated with (and alongside) the white spots were blisters in the paint. A 30X photo-micrograph of several paint blisters is shown on the left.

The blister shown above was opened with a probe and the paint “cap” was peeled back. This exposed a white powder under the paint. The powder is zinc hydroxide. This forms when freshly galvanized surfaces are exposed to pure water (rain or condensate), and the wet surfaces are not allowed to dry (i.e. in a stack). The zinc reacts with the water and forms the hydroxide. The arrow points to the exposed powder. Just to the right of the arrow there is evidence of iron oxide.

Thus, in less than a year the zinc layer (on trhe order of 0.001″ thick) has been penetrated. All this occured under the paint. Therefore, this is a manufacturing defect that must be corrected by the material supplier.