Many products are packaged in glass bottles sealed by a cap with a pliable polymer liner. Some products such as jelly are sealed hot and this creates a vacuum seal. Other products such as soda and beer are sealed under pressure. Proper sealing requires that the bottle seal surface be smooth and not have a leakage path. Read Consulting was asked by a cosmetic manufacturer to determine why their products were leaking.

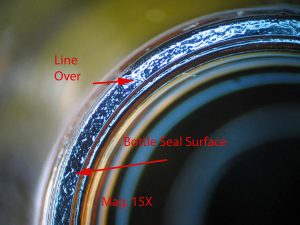

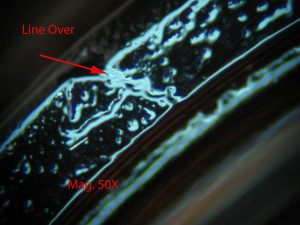

A microscopic examination was performed on the cap and bottle seal surfaces. There was no apparent problem with the cap seal. However, the seal surface on the top of bottle finish was rough and there was a line over defect that prevented proper sealing. The line over provided a leak path.