Introduction

Transparent glass tiles were mounted to the surface a new swimming pool. These tiles were set onto the walls and floor of the pool using a white thin set mortar. After installation the pool walls where defect free. However, some time after the pool was filled with water many of the tiles showed cracks.

Results Summary

After removal, it was discovered that at least 85% of the tiles showed cracking. These glass tiles had not been properly annealed, and they had high residual tensile stresses. In addition, the glass was not uniform in composition. Point defects on the tile backside initiated cracks that spread and cracked the tiles.

Sample Description

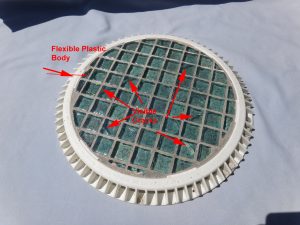

The tile samples submitted for examination consisted of a drain cover with approximately 48 glass tiles mounted on top (Figure #1). The body of the drain cover is made of a flexible plastic. The drain body is not rigid, and because of this, it effectively acts as an expansion joint. Thus, absence of an expansion joint cannot be blamed for the cracking of these glass tiles.

Discussion

The tiles examined are of very poor quality. They contain high residual tensile stresses. In addition, the glass is not homogeneous. All these factors have caused these tiles to crack during and after installation.

Observations

1. Over 85% of the tiles had cracking at the corners on the bottom of the tiles.

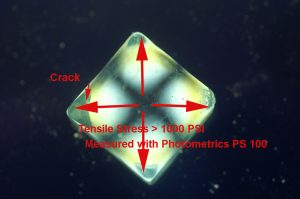

2. Polarimeter measurements show that these tiles have large residual tensile stresses.

3. Many of the tiles show non uniformities in composition.

4. Photomicrographs indicate that the thin set was inside the cracks. This indicates that the cracking initiated when the thin set was still fluid.

5. Fractography determined that the cracks grow from a point initiation on the backside. The cracks have numerous “crack arrest lines”. The glass tiles failed in fatigue.

Procedure

Tile Removal

The tiles that were examined made up a drain cover (Figure #1`). They were encased in a plastic frame (most likely Nylon). The plastic frame was removed and the tiles were soaked in Muriatic acid which softened the thin set and the grout. To prepare for examination, the tiles were then separated and cleaned with muriatic acid.

Figure #1: Photographs of the as received drain cover with the subject tiles. There are numerous visible cracks that go to the tile top surface. In addition, there are numerous corner cracks on the tile bottoms that are not visible,

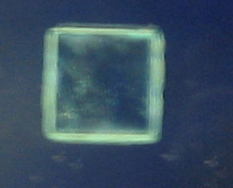

Figure #2: Photograph of a representative tile with corner cracks.

Polarimeter Examination

A Photometrics PS 100-BS polarimeter was used to examine each tile. The polarimeter uses polarized light to measure stress in transparent objects. In addition, it will reveal any non homogeneous glass.

Figure #3: Stress pattern of a representative glass tile as viewed through cross polarizers. The stress in this tile is >1000 psi tensile. The stress in these tiles is always tensile and often exceeds 1000 psi.. This tensile stress is near the long term strength of the glass. Thus any additional stress can cause cracking.

Figure #4: Shown for comparison is the stress pattern of an annealed glass tile as viewed through cross polarizers. There is no pattern because there is no stress.

Glass Fractography

During examination, cracked tiles were broken apart to reveal the fracture surfaces. Using a microscope, markings on the fracture surfaces were traced back to the crack origin. The origin was then examined microscopically to determine the cause of failure. All the fractures originate at a point defect on the tile’s bottom surface. This is the downside in contact with the thin set. The crack grows incrementally from the origin. In some cases there is thin set on the fracture surface. Thermal and tile mounting stresses are additive to the preexisting residual stresses described above. Over time the initiated crack grows to the point that it is visible to the naked eye. In other cases, the corners crack, but these cracks are not visible because they do not go to the top surface. Initially it was thought that approximately 30% of the tiles were cracked. In reality more than 85% were cracked.

Figure #5: Representative fracture pattern of these tiles. The fracture initiates on the backside of the tile and propagates incrementally as it goes through the glass tile to reach the top surface.