Product liability is strongly dependent on part quality. This is a big issue when changing part suppliers, and there are times a product liability expert must be hired to examine parts from the new supplier.

Product liability is strongly dependent on part quality. This is a big issue when changing part suppliers, and there are times a product liability expert must be hired to examine parts from the new supplier.

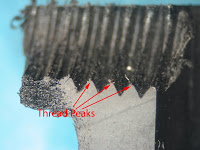

In this case, the supplier of a molded nylon part was changed and plastic failure analysis tests showed that the thread strength of the replacement part was inadequate. The possibilities considered were a change in the polymer, improper glass filling and incomplete thread geometry. The new supplier actually failed on all three counts. He substituted a different polymer, he used shorter glass fibers, and he did not properly mold the part. A failure analysis expert performed a root cause failure analysis which indicated that incomplete molding of the threads was the main cause of the decrease in strength. A failure analysis expert cross-sectioned representative parts and found the female threads were incomplete, and these provided inadequate strength. The cross-section photomicrograph on the upper left shows the representative threads of a part from the original supplier. Upper right is that of the alternate supplier. One can see that the alternate supplier had formed incomplete threads.