Introduction

Read Consulting LLC, a California failure analysis laboratory, was asked to perform a failure analysis on Pogo pin connectors that exhibited intermittent contact when the contact pin was depressed. These are less expensive Pogo pin connectors that were being evaluated to replace those from a domestic supplier. The appearance of the subject pogo pins was identical to that of the present pins; however, their performance was unacceptable due to interrupted connections.

Results Summary

The intermittent contact problem was caused by poor plating on the interior wall of the Pogo pin connectors. This resulted from the fact that the outer case of these Pogo pin connectors had a bottom (i.e. it is a blind hole). Due to the high aspect ratio of depth to diameter it was impossible to clean and plate the interior wall. The standard pogo pin was a bit shorter and it had a removable cap at the bottom; thus, plating was done on an open ended tube.

Objective

Determine the cause of the intermittent contact problems with recent shipments of POGO pins. Compare these pins with the traditional supplier that did not exhibit intermittent contact.

Test Procedure

Using a low power microscope, dissect a representative Pogo pin connector that shows intermittent contact problems and photographically document the interior structure with a low power microscope. Perform a similar procedure on a pin that does not have contact problems.

Results

The results are summarized by the photomicrographs shown below:

Figure #1: Photo-micrograph of the two Pogo pins evaluated for this report. The less expensive pin on top is from an off shore supplier, and it exhibits intermittent contact problems. The lower pin is from a domestic supplier, and it shows good repeatable contact performance.

Pogo Pin Exhibiting Intermittent Contact Problems

Off Shore Supplier

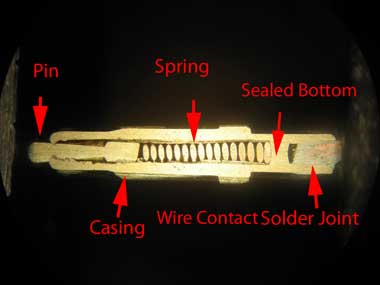

Figure #2: Photomicrograph of a cross section of a Pogo pin exhibiting intermittent contact problems. This pin exhibits a momentary open when depressed. In this view the pin is depressed. It appears as if there is good contact between the spring and pin. Thus, the electrical contact to the outer casing must be through wall contact not through the spring to the bottom of the case. Note that the “casing” has a solid bottom (it’s a blind hole); therefore, this is a deep blind hole that is impossible to clean and plate to the bottom. (Mag. 20X)

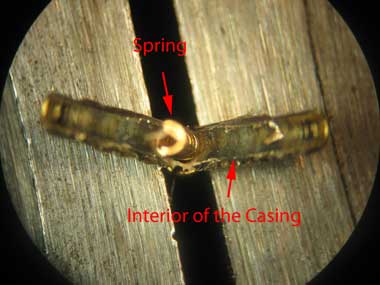

Figure #3: Photomicrograph of a POGO pin. The shape of the pin bottom suggests that the pin would be pushed side ways to make contact with the wall. The plating on the pin seems adequate. (Mag. 40X)

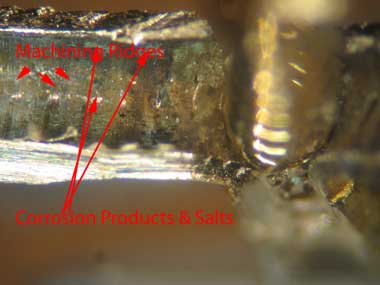

Figure #4: Photomicrograph of a split Pogo pin. The plating on the spring is adequate; however, the plating on the interior wall is (for the most part) non-existent. In addition there are residual plating salts and corrosion bi-products on the inner wall that will interfere with electrical contact. (Mag. 20X)

Figure #5: Photomicrograph of a split Pogo pin. Visible on the interior wall of the case are horizontal machining marks that will impede pin movement. In addition, the plating on the interior wall is non-existent. In addition there are residual plating salts and corrosion bi-products. This condition worsens toward the bottom of the casing. The Pogo pin case is a blind hole; therefore, it is impossible to plate properly. There is no contact made by the spring to the bottom of the case. (Mag. 40X)

Pogo Pin with No Intermittent Contact Problems

Domestic Supplier

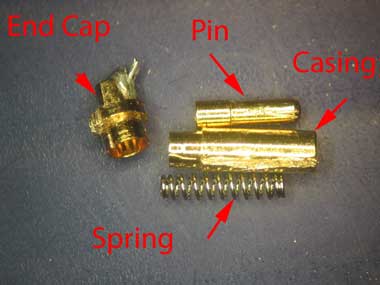

Figure #6: Assembly parts of the “good” (domestic) Pogo pin. These consist of a casing, casing end cap, spring (not gold plated) and a gold plated pin with a flat bottom. This case can be through cleaned and plated.

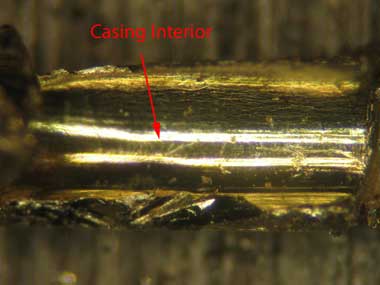

Figure #7: Photomicrograph of the interior wall of the “domestic” Pogo pin case. It is smooth and fully gold plated. In addition, there are no salts or oxides to prevent electrical contact. Complete plating of the interior wall is possible because the case is open at both ends which allows proper cleaning and plating. (Mag. 20X)

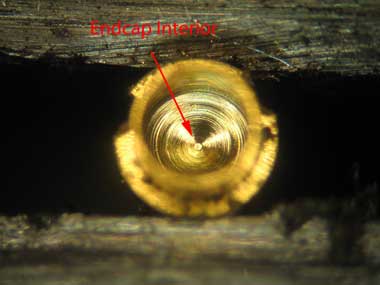

Figure #8: Photomicrograph of the interior of the end cap Pogo pin case. It is very clean and fully gold plated. In addition, there are no salts or oxides to prevent electrical contact. This allows good electrical contact between the spring and the end cap at the bottom of the case. This Pogo pin doesn’t rely on side wall contact. (Mag. 30X)