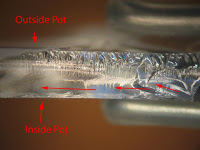

A failure analysis was performed on a glass coffee press. In this case the glass coffee pot is a 0.085″ thick borosilicate glass 3.7″ diameter cylinder that is 7″ high. It had received a blow on the top rim, and it broke into approximately 10 pieces. Because the pot is a cylinder, the blow from the outside on the rim created tensile stress on the inside of the pot and compressive stress on the outside of the pot. This is reflected in the fracture surface above. The crack traveled faster on the inside half of the glass fracture surface. It finished as twist hackle on the outside half of the glass fracture surface.

A failure analysis was performed on a glass coffee press. In this case the glass coffee pot is a 0.085″ thick borosilicate glass 3.7″ diameter cylinder that is 7″ high. It had received a blow on the top rim, and it broke into approximately 10 pieces. Because the pot is a cylinder, the blow from the outside on the rim created tensile stress on the inside of the pot and compressive stress on the outside of the pot. This is reflected in the fracture surface above. The crack traveled faster on the inside half of the glass fracture surface. It finished as twist hackle on the outside half of the glass fracture surface.

Materials Failure Analysis and Process Engineering

Read Consulting Failure Analysis

Thomas L. Read, PhD,

1435 Fulton Road Santa Rosa, CA

Phone: 707-494-5089

email: info@readconsulting.com

Registered Professional Engineer

Thomas L. Read, PhD., CEO

Registered Professional Engineer

Certificate No. MF002174

State of California.