Introduction

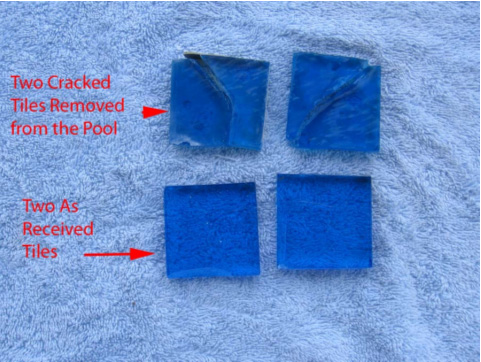

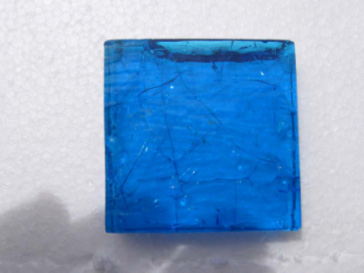

The glass expert at Read Consulting was asked to evaluate four glass tiles (Figure #1) associated with the water line of a swimming pool. Two of these tiles were cracked tiles that were removed from the pool, and two were new (as received) tiles from the supplier.

Summary of Results

- Glass tile cracking occurred during mounting in the thin set mortar.

- Contrary to the manufacturers statements, the subject glass tiles do not pass ASTM 484-99.

Procedure

Cracked Tiles: Both cracked tiles were held together by grout that had seeped into the cracks during mounting in thin set mortar. As received, they could not be pulled apart to perform a root cause failure analysis by examining their respective fracture surfaces. Both were soaked overnight in Muriatic acid (10% HCl). This softened the grout and allowed the two cracked tiles to be pulled apart to expose the fracture surfaces. Once parted, a glass failure analysis was performed.

“New Tiles”: These were subjected to ASTM C 484-99: “Standard Test Method for Thermal Shock Resistance of Glazed Ceramic Tile”. This standard specifies “glazed ceramic tiles”; so, the subject glass tiles do not fall into this category. However, the manufacturer specifies that these tiles pass this test. In addition, these glass tiles are a direct replacement for glazed ceramic tiles. Thus, they should perform on a par with them. ASTM C 484-99 evaluates the tiles ability to survive ten thermal cycles from 15° C to 145° C without showing visible defects. Figure #1: Photograph of the four tiles submitted by Texas Pools for

Figure #1: Photograph of the four tiles submitted by Texas Pools for

evaluation. These tiles are 2” X 2” X 0.385” thick.

Results and Discussion

Failure Analysis of the Two Cracked Tiles

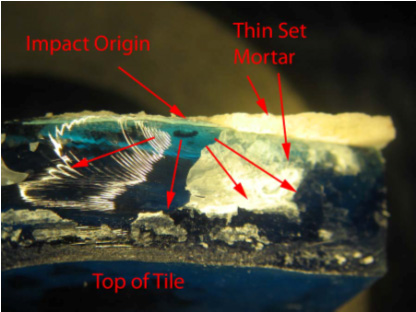

Both cracked tiles failed from “point impact” to the backside of the tile during mounting the tiles in thin set mortar. This could have happened when a rubber mallet was used to level the tile with the general plane of the other tiles. Possibly, there was a hard particle that was driven into the back of the tile when it was hit with the “alignment” mallet.

Figure #2: Photomicrograph of the fracture surface of one of the cracked tiles. Still visible is some of the mortar that had seeped into the crack when the tile was pressed onto the thin set for mounting. This fracture surface indicates that this tile failed as a result of point contact impact. This could have happened when a rubber mallet was used to level the tile with the general plane of the other tiles. Most likely, there was a hard particle that was driven into the back of the tile when it was hit with the “alignment” mallet.

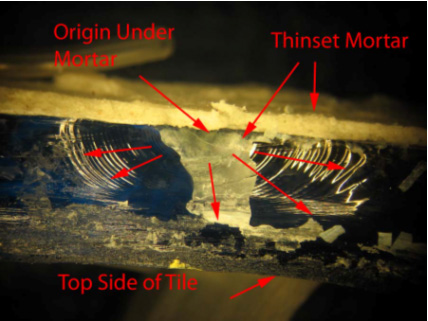

Figure #3: Photomicrograph of the fracture surface of the other cracked tile. The failure is, more or less, identical to the first tile. Again this failure occurred as a result of impact of a hard particle to the backside of the glass tile.

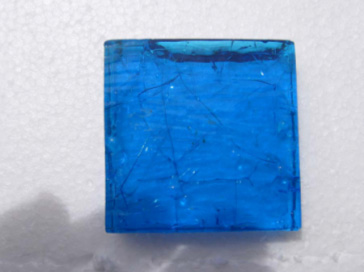

Evaluation Thermal Shock Testing per ASTM C 484-99

Both “new” tiles showed severe cracking after only one cycle from 15° C to 145° C back to 15° C. This proves that these tiles cannot pass this test. Thus the manufacturer’s statement that these tiles pass this test is incorrect and miss-leading.

Discussion

The failure analysis experts at Read Consulting have examined, tested and performed failure analysis on numerous types of glass pool tiles. Below is a list of general observations and comments derived from these evaluations.

- Glass tiles are not a direct replacement for glazed ceramic tiles.

- No glass pool tile has been able to pass ASTM C 484-99 thermal shock testing.

- Glass tiles are more fragile than most glazed ceramic tiles. Thus, one should be extremely careful when mounting them in thin set. The tile setter should use thicker thin set and press the tile into position with a relatively soft tool.

- It is recommended that opaque glass tiles be used. Clear glass tiles transmit infrared light that can heat the cured thin set behind the glass tile and put the tile’s backside in tension. This can cause cracking.

- Glass tiles are more prone to cracking and chipping when being handled individually.

- Thicker glass tiles are more susceptible to thermal shock.

Figure #4: Photograph of one of the two tiles after one cycle from 15° C to 145° C back to 15° C. There are a number of cracks that appeared after only one cycle.

Figure #: Photograph of one of the other tile after one cycle from 15° C to 145° C back to 15° C. Again, there are a number of cracks that appeared after only one cycle.