California Glass Expert Performs Glass Failure Analysis on a Broken Sauce Bottle

Often when a glass bottle fails and the user is injured, there is a suspicion that there is a manufacturing defect in the bottle. However, only a detailed failure analysis can determine the root cause of the failure. Figure #1 is a photograph of a bottle failure which caused an injury. The bottle broke into two pieces, and the Wallner lines indicated that the origin was buried in the neck piece.

Figure #1: Photograph of the re-assembled bottle. The origin is buried in the neck.

Figure #2: Close up of the crack in the neck after the paper label had been removed. The arrow indicates where the crack origin was found by the failure analysis described below. The shape of the crack indicates that the bottle failed as the lid was being twisted off.

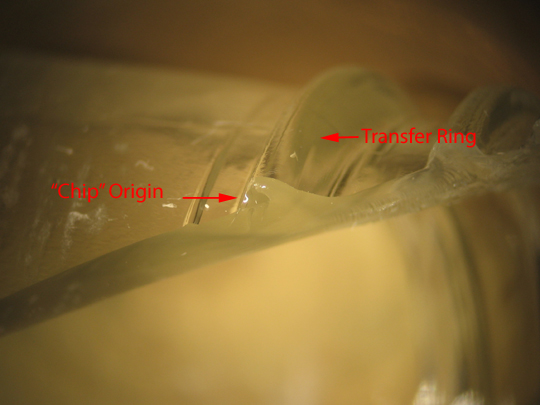

Before a failure analysis can be performed, the fracture surfaces must be exposed. To do this, the neck was cut open from the opposite side of the neck. This allows the piece to be opened to expose the failure surfaces. Figure #3 is low power photomicrograph of the portion of the fracture surface containing the origin.

Figure #3: Low power photomicrograph of the transfer ring with the origin (a chip on the transfer ring), indicated by the arrows (Mag 20X).

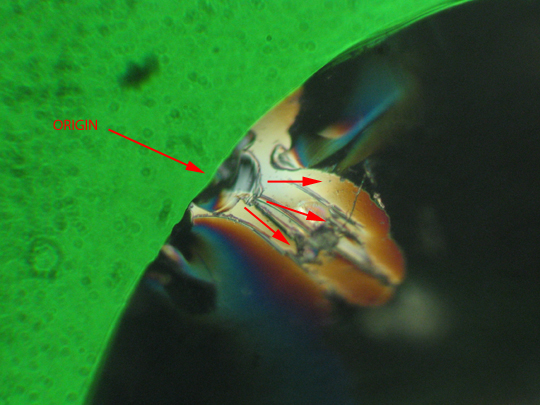

At higher magnification one can see that the failure originated at a chip on the transfer ring. This bottle had been opened before the failure event. This is demonstrated by the presence of sauce on the threads (Figure #5). Sauce on the threads also increases the torque to open the bottle. The sugar in the sauce acts as an adhesive between the lid and the top and the adhesive bond must be broken before the lid can be twisted off.

Figure #4: Nomarski photomicrograph of the failure origin (Mag 250X),

Figure #5: Photograph of the bottle and lid immediately after the lid was removed. The threads on both are coated with sauce. This indicated that this bottle had been opened prior to the failure. Sauce on the threads will increase the torque needed to remove the lid.

Conclusion: This failure resulted from handling damage which resulted as a chip on the transfer ring. Twisting the lid off caused bottle to fail.The failure was not caused by a manufacturing defect.