Introduction

The tempered glass expert at Read Consulting LLC performed a glass failure analysis on a failed aircraft windshield (Figure #1).

Result Summary

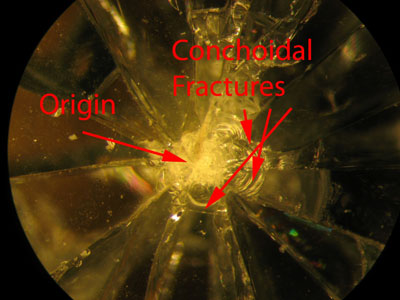

The failure of the aircraft windshield was caused by the impact of a pointed hard object traveling at a high speed. This could include the leading edge of a large piece of ice. This is demonstrated by the presence of crushed glass at the origin (i.e. glass powder) and subsurface conchoidal cracking which is typical from the impact from a small object.

Description of Aircraft Windshield

The subject windshield was made from laminated glass. The outer layer was made from 5mm thick thermally strengthened glass. There is a heating grid between the two layers of the laminated glass. It is believed that the polymer interlayer is polyvinyl butyral. The dimensions are approximately 20” X 28” X 28” X 25”. The glass on the convex side of the windshield has failed. The fracture pattern of the failed glass indicates that it is made of heat strengthened glass.

Objective

Perform a failure analysis to determine the cause of failure.

Results

The results of this glass failure analysis are summarized by the photographs below.

Figure #1:Photograph of the failed windshield taken from inside the cockpit.

Figure #2:Photograph of the failed windshield taken from the inside. It is a curved piece of laminated glass sealed into a metal frame.

Figure #3:Close up photograph of the fractured outer surface of the subject windshield. The origin is indicated.

Figure #4:Photomicrograph of the failure origin. At the origin there is crushed glass. In addition, one can see subsurface conchoidal fractures. These result from impact by a small hard object traveling at a high speed. The energy of impact was absorbed by the polymer interlayer, and the interior pane of glass was not damaged (Mag. 40X).